Compressed Air Efficiency Study

PTI currently performs compressed air efficiency studies at facilities to increase the efficiency of the plant air or compressed gases. Typical energy savings with a payback of 1-2 years for repair recommendation implemented are average. Your plant may even qualify for rebates through your local energy provider.

Oil Analysis

Oil analysis works for any type of lubricating system and can be applied to engines, gearboxes, bearings, compressors, etc. Proper lubrication of machinery is a significant contributor to the long and problem-free life of machinery. Implementing a premium plant lubrication program begins with an assessment of the current situation, Monitor changes and improvements, proper training and implementation & Continuous improvements, and evaluations.

Predictive Technologies Inc, implements reliability programs using oil analysis. Oil analysis is the analysis of the oil sample's properties, suspended contaminants, and wear debris. PTI will routinely go onsite, take oil samples and get them analyzed in a laboratory. After the analysis is completed, you will receive a report detailing all of the things your oil contains, along with the correct levels that it should have. This is compared to a reference sample of the original oil. These reports help you get to know your equipment better and improve.

Creating such routine activity will help you be informed of the health of the oil and machinery, which gives you a window into your equipment. This will help you identify problems and resolve them at the early stages of that failure. This will result in less downtime and overall save you money.

Acoustic Analysis

Acoustic analysis can address severe structural vibration, fatigue problems, or high levels of noise in a coupled fluid-structure system.

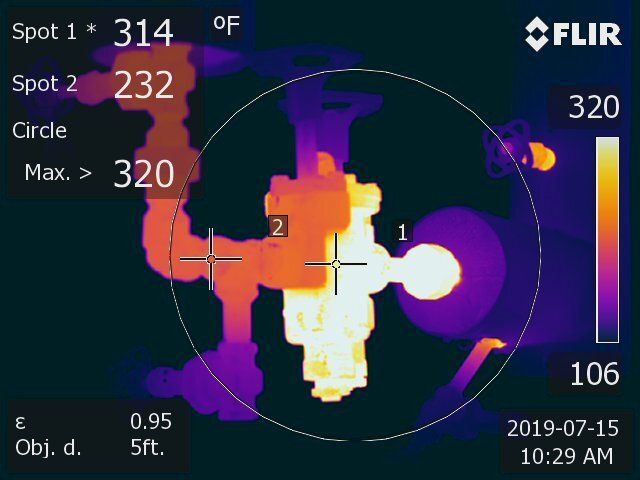

Infrared thermography is an excellent condition monitoring tool to reduce maintenance costs on mechanical and electrical equipment and detect developing problems. IR trending is a software based program to track changes and diagnose machine failures before they occur. Reports include, cost justification, plant summary, exceptions, and baselines.

Share On: