NDT Services

Free Quotes | Certified Experts | Get a Detailed Service Report

Free Quotes

Certified Experts

Get a Detailed Service Report

NDT & Inspection Services

Ultrasonic thickness Testing

Ultrasonic Testing (UT) uses high-frequency sound energy to conduct examinations and measurements. Ultrasonic inspection can be used for flaw detection/evaluation and dimensional measurements.

In the field of industrial ultrasonic testing, ultrasonic thickness measurement ( UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface.

Visual inspection Testing

Magnetic Particle Testing / WFMT

The magnetic particle examination method is used to detect cracks and other discontinuities on the surfaces of ferromagnetic materials. The sensitivity is greatest for surface discontinuities and decreases rapidly with the increasing depth of discontinuities below the surface. Typical types of discontinuities that can be detected by this method are cracks, laps, seams, cold shuts, and laminations.

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization.

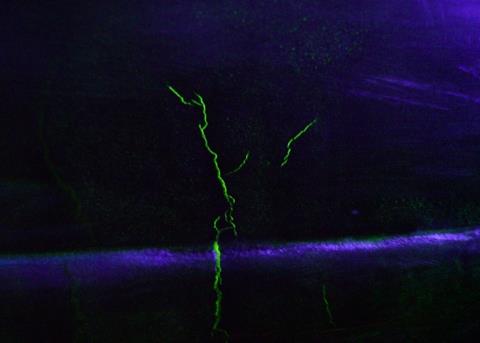

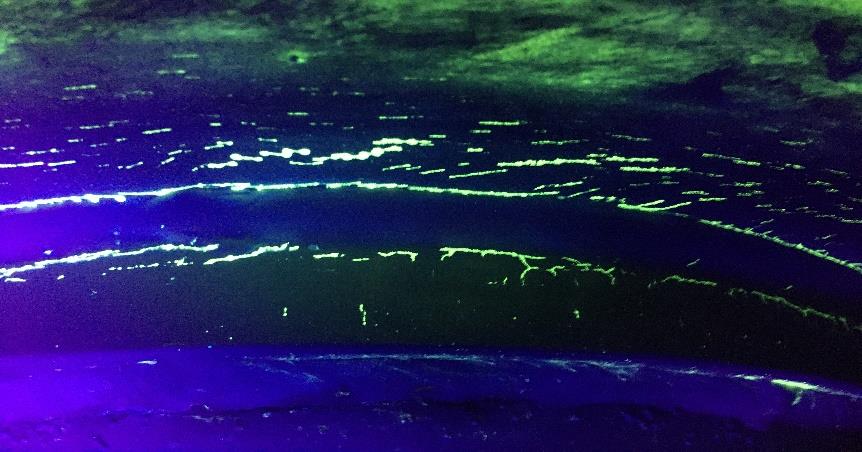

dYE Penetrant Testing

The liquid penetrant examination is an effective means for detecting discontinuities that are open to the surface of nonporous metals and other materials. Typical discontinuities detectable by this method are cracks, seams, laps, cold shuts, laminations, and porosity.

Dye Penetrant Inspection (DPI) is widely used to detect surface breaking flaws. This non-destructive testing technique, also known as liquid penetrant inspection (LPI), is a cost-effective method used to locate surface-breaking flaws such as cracks, porosity, laps, seams, and other surface discontinuities.

Share On: